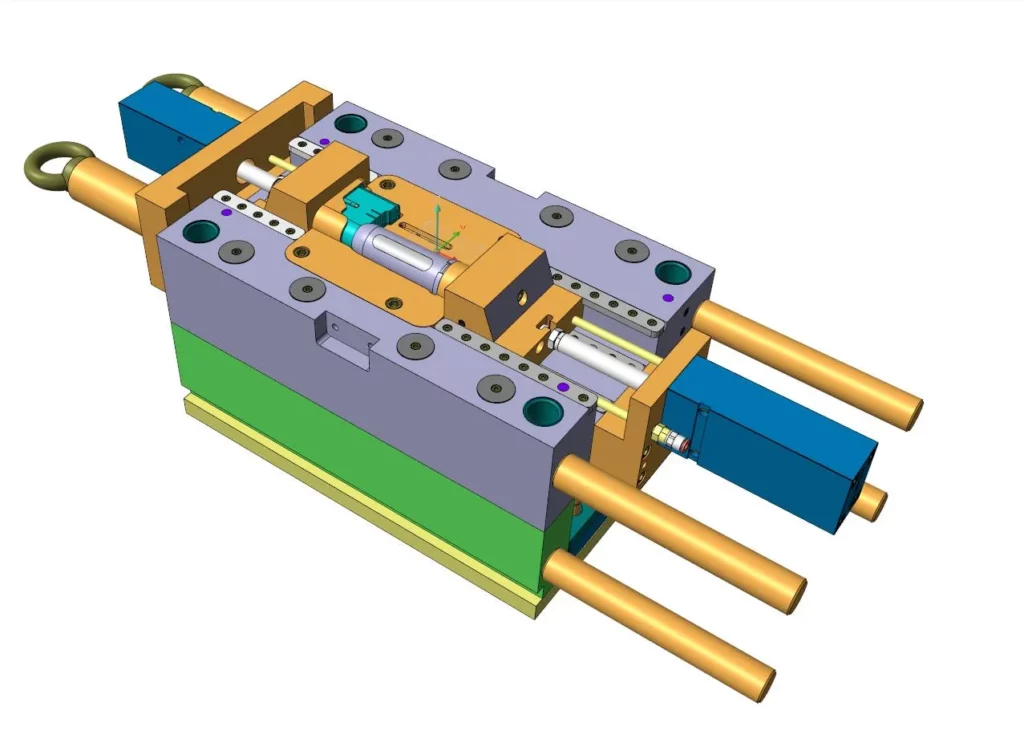

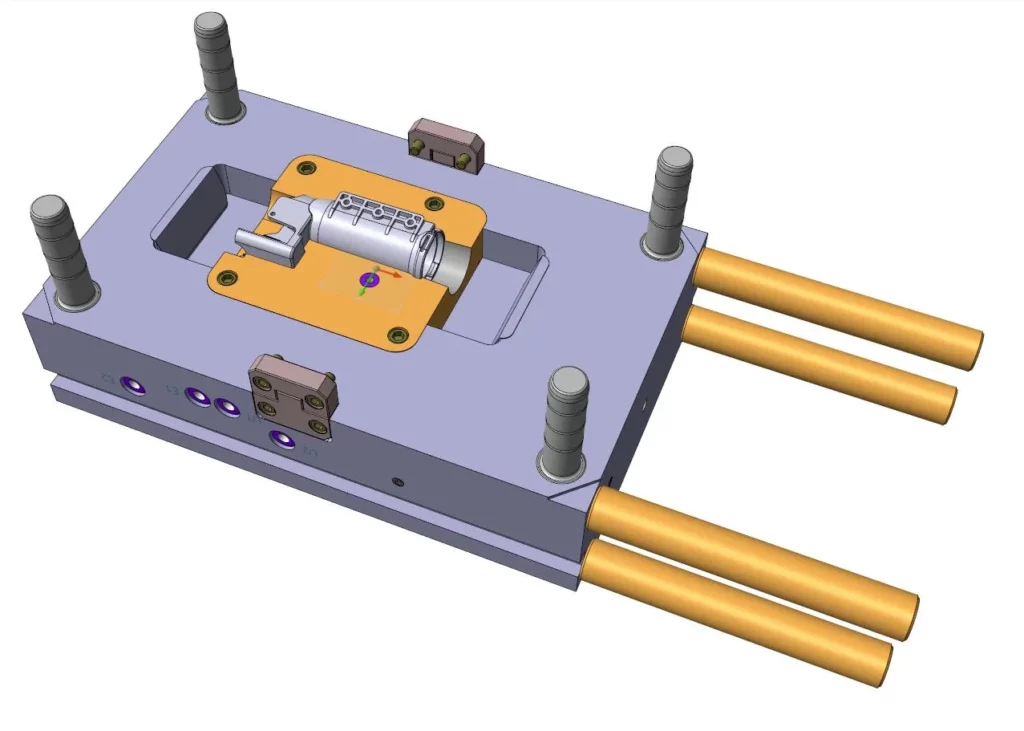

In technical molding, success often hinges on invisible details: a calibrated draft angle, a hidden injection point, an offset that ensures structural consistency. In this project, every micro-area was analyzed and optimized to match the material behavior and adapt it to the industrial scale with maximum precision.

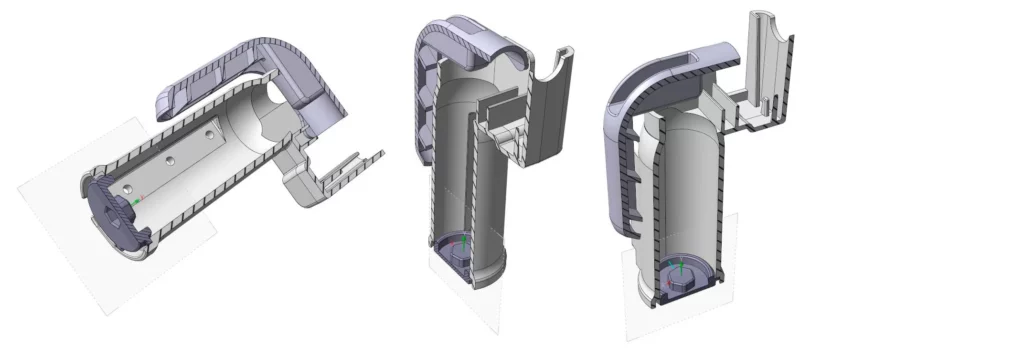

Armal, a leader in the mobile sanitation services sector, requested a specific component for their Spray Unit, designed to deliver a delicate active ingredient while also resisting light but repeated stresses. The MPT Codesign team worked on three technical elements made of PA6 GF30, a material chosen for its strength and stability, aiming to achieve a smooth, flawless surface directly from the mold. This was all to be achieved with a two-cavity mold, ready for in-house production and in line with the aesthetic and functional standards required during assembly.