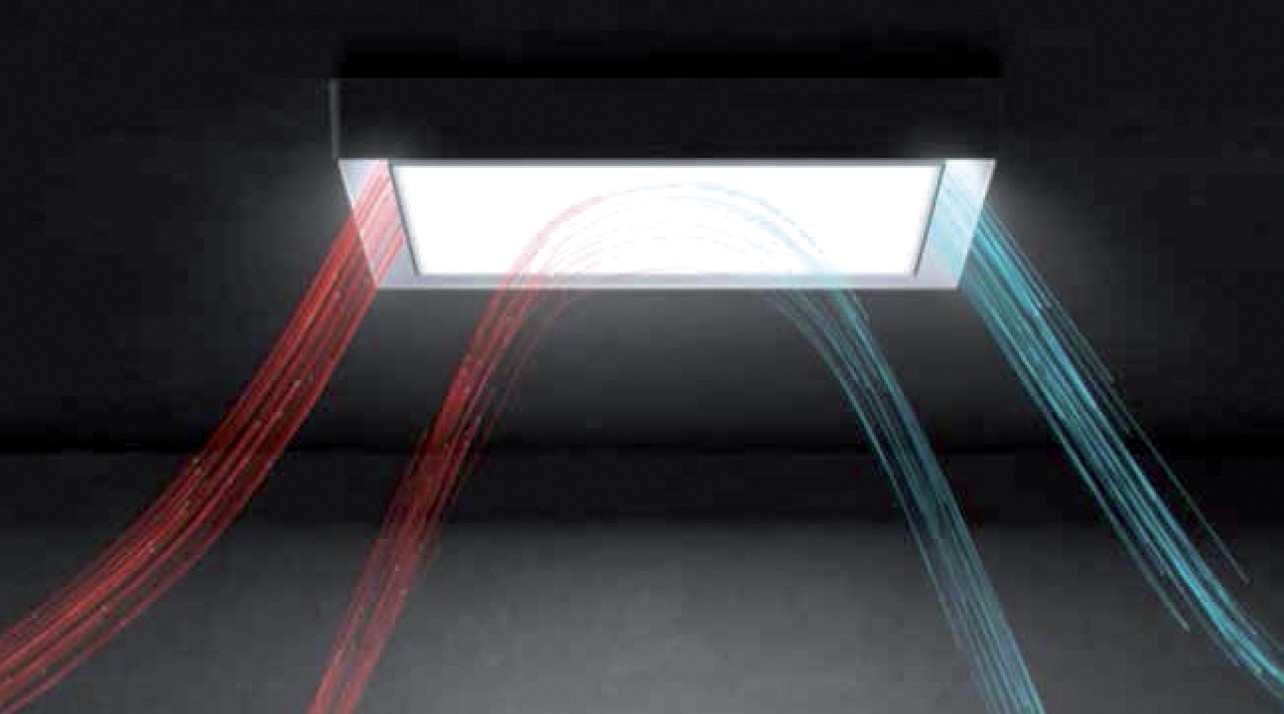

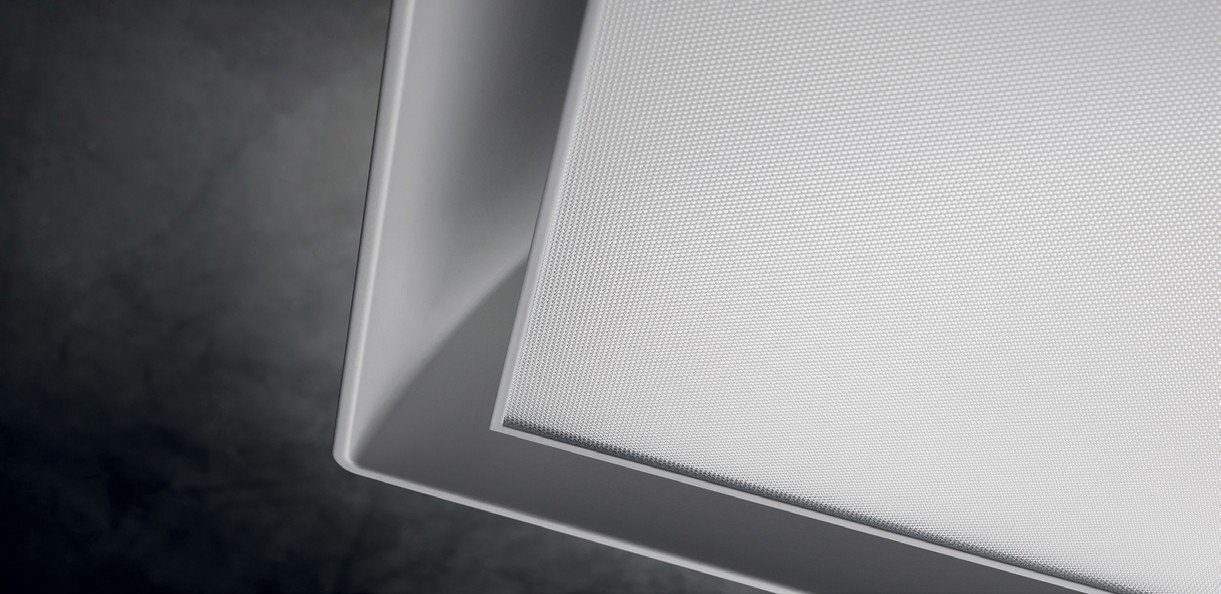

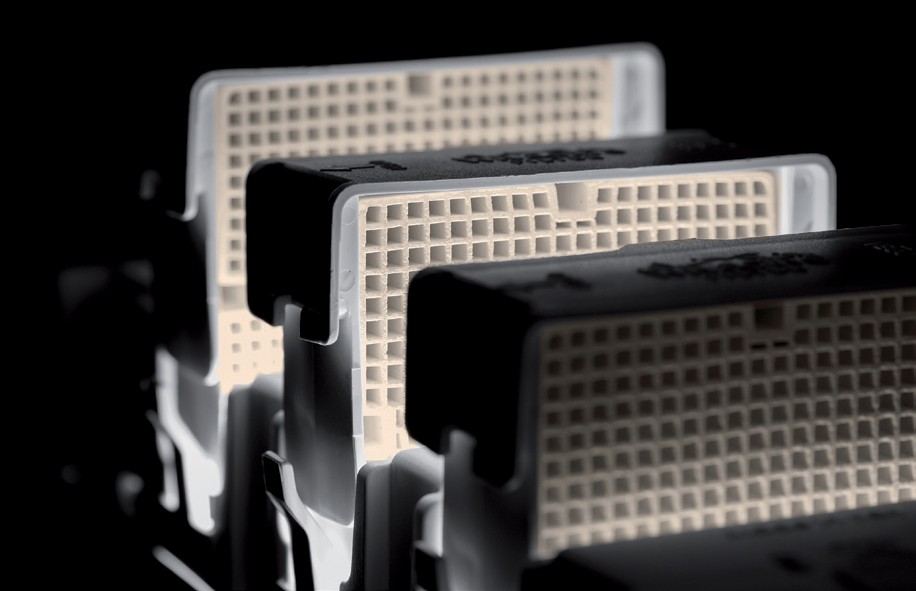

Between the external structure in ABS and the central panel in PMMA there is a groove for the recirculation of air from which a calibrated light blade filters.

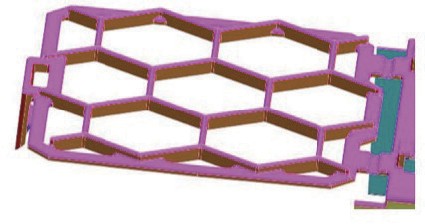

From the point of view of industrialization, the creation of this gorge was far from simple. If the dimension of the entire ABS panel (60 x 60 cm) have involved a careful study to avoid deformation, even more this threat has required special design and molding.

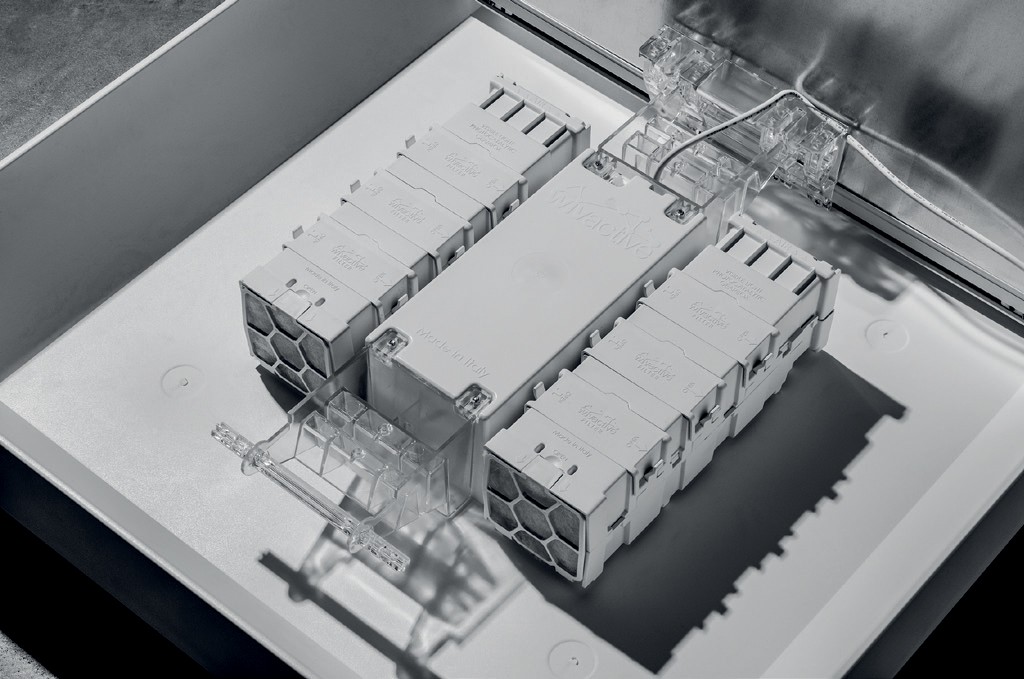

During the design of the moulds, we carried out 6 Moldflow analyses, until we found the right configuration to build the hot chamber.

Moreover, for the construction of the equipment we have adopted special steels, inserting shaped cooling, made with additive technologies, along the perimeter of the piece. This has allowed us to guarantee an optimal moling result.

Customers are looking for reliable partners who can solve problems and problems with effective solutions.

The Wivactive project involved a rigorous study of the dimensions, tolerances and careful design and construction of the molds used to produce them.