HOW TO INDUSTRIALIZE AN IDEA

LOVINO is a desk organiser, object holder, pocket emptier and jewelery box inspired by Ovetto, Soldidesign’s best-selling product for separate waste collection. LOVINO recalls the ancient Persian, Roman and medieval traditions which saw the egg as the metaphor of everything, ideal to give as a sign of good luck.

Being a free-standing, elegant and premium design object, the customer needed the finished product to be:

- Smooth and pleasant to the touch

- Polished and free of paint

- Functional and practical to open and close

- Resistant and very stable

- Ecological

LOVINO, however, was still just an original idea translated into a 3D model. So MPT Plastica’s technical office performed an accurate MoldFlow analysis to optimize the mathematics of the product and make it suitable for the large-scale injection molding process.

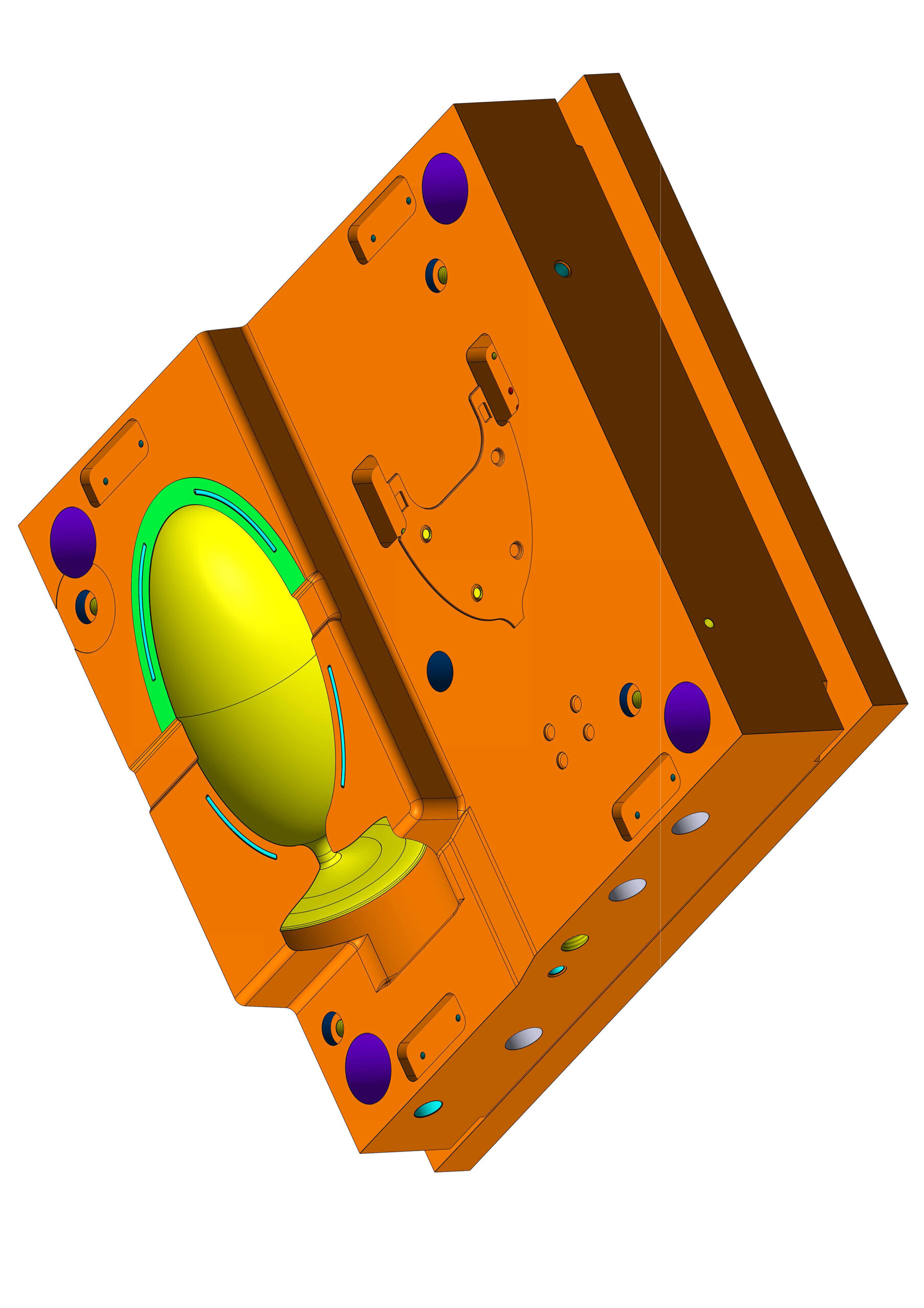

Once the geometries of the individual pieces had been defined for a perfect coupling of the semi-parts, a single mold was designed and built for all the components which would then be assembled manually by the customer.

For the creation of LOVINO it was chosen to use ABS in various colors with percentages of recycled material, for its impact resistance and toughness properties.