Today, the news of a street-cleaning robot autonomously performing practical functions and interacting with people is no longer surprising. However, it was truly a futuristic idea 15 years ago when Professor Paolo Dario, Director of the BioRobotics Institute at S. Anna in Pontedera (Pisa), involved us in the DustCart project.

At that time, environmental sustainability and the circular economy were still relatively uncommon approaches in the plastics transformation industry. That’s why we decided to support the ambitious efforts of the Scuola Superiore S. Anna to promote innovation and sustainability in waste management.

After this significant experience at the highest levels of experimental research, we can give a confident and promising answer to the question in the title: Yes, post-consumer plastics can be used in the production of high-tech components.

DustCart. The Recycled PET Street-Cleaning Robot that Traveled the World

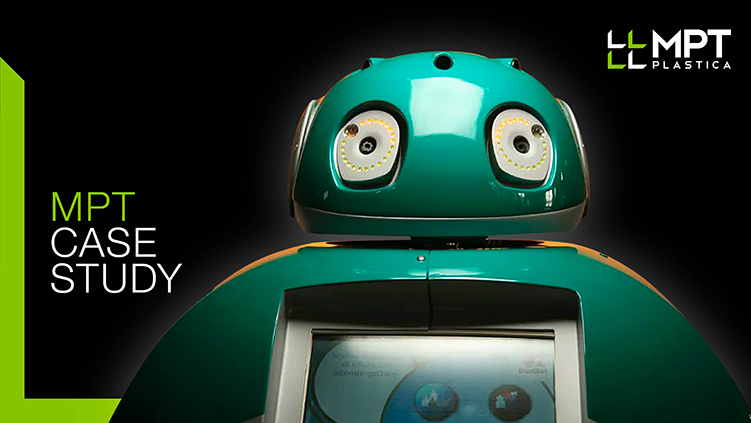

DustBot is the name of the technological platform developed by the BioRobotics Institute of Scuola Superiore S. Anna for optimizing waste management and improving environmental hygiene through a network of small, autonomous, cooperating robots.

Such an innovative and ambitious project has traveled the world, reaching Japan and America after traversing all over Europe.

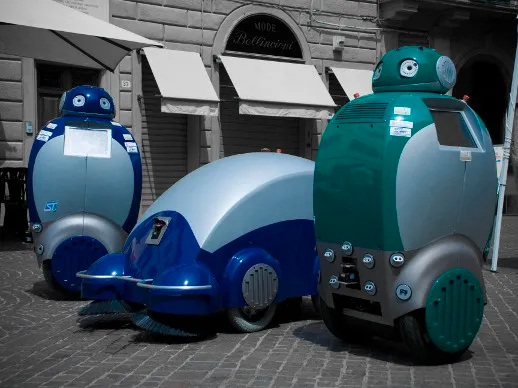

The European project coordinated by Scuola Superiore Sant’Anna envisioned robots capable of operating in urban environments such as squares, streets, alleys, and parks to clean them of waste and debris and monitor the air for atmospheric pollutants.

The idea of a fully automated machine, capable of going to citizens’ homes, navigating urban routes, collecting sorted waste, and taking it to landfills, was already cutting-edge for the time. The real turning point in terms of sustainability and circularity was that the robot itself was made from recycled waste: post-consumer PET.

The bet was: if there is even a robot made of recycled plastic, then making a scooter, an appliance, or anything else must be much simpler. This is the message of change and environmental responsibility launched by the waste-collecting robot DustCart.

Robot on Demand

The electronic street sweeper DustCart stands at 1.50 meters tall, 77 cm wide, moves on two wheels powered by an electric motor, has a range of 24 km, and can reach speeds of 16 km/h. Movements and navigation are managed by a GPS satellite system aided by a secondary system of buoys that work via ultrasound. The result: it arrives at the desired location with an accuracy of centimeters. Through the use of lasers on its wheels, it can also identify and avoid obstacles on its path.

Some have likened it to the first truly functioning street-cleaning robot like Wall-e, the main character of a Disney animated film. Of course, DustCart doesn’t fall in love, but researchers and the public have fallen for it.

It all began with the European DustBot project (Dustbot-Networked and Cooperating Robots for Urban Hygiene) in 2006 coordinated by Paolo Dario, director of the Sant’Anna Valdera campus in Pontedera (Pisa), which received an initial €3 million funding from the European Union and became the project leader. The research immediately focused on creating a machine that could use preloaded maps, receive topographic coordinates on where to go, collect garbage bags, and take them to landfills. DustCart operates on-demand, like a taxi: the citizen indicates with a phone call to the service control center the time when they will be on the street for garbage collection, the robot arrives at the agreed time, collects the bag, and continues its cleaning route.